Indirect supplies are the materials which are too onerous to trace to the product to be direct materials. This includes issues like glue, solder (a low-melting alloy used to hitch metals collectively), and nails. This is a direct cost as a result of it’s easy to measure how many journey mugs a worker could make in an hour and therefore decide the direct labor cost per mug. If a employee can make 40 mugs per hour and the worker makes $20 per hour in wages and benefits we are able to divide the fee per hour by the variety of mugs to get the price per mug. Well we need the machinery to mildew the plastic, a building to deal with the machinery, utilities to make the equipment work, computer systems for the supervisors, managers, receptionists, purchasers and others within the group.

Costs affected or driven by time have increased considerably, yet time doesn’t feature in conventional price systems as a cost driver. Interest price is treated as another interval price, whereas it could contribute considerably towards bringing the product to its current status. Service associated costs like professional companies, banking services, insurance coverage services have increased significantly in the previous few decades. Labour, as a foundation for assigning manufacturing overhead, is irrelevant as it’s considerably less than overhead and lots of overheads don’t bear any relationship to labour value or labour hours. ABC system addresses the therapy of all overhead associated prices linking with cost drivers and price swimming pools.

Chapter 6the Traditional Two Stage Cost Allocation Strategy

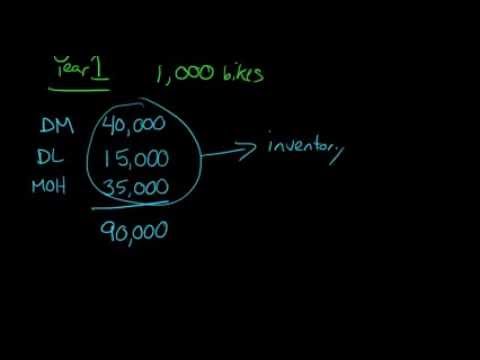

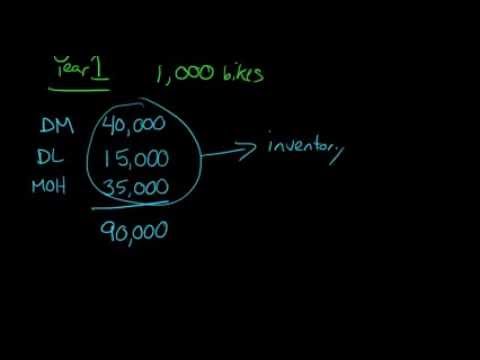

Now that we have all of those product costs, we need to classify them additional. Product, or manufacturing costs, may be classified into direct supplies , direct labor , and manufacturing overhead . Until information collection is better automated, the use of work elements to regulate actions in large projects is likely to be troublesome to implement. However, sure segments of project actions can revenue tremendously from this sort of organization. Materials contain solely a subset of all price accounts and project activities, so the burden of information collection and control is much smaller than for a complete system. Moreover, the advantages from integration of schedule and price data are notably noticeable in supplies control since delivery schedules are directly affected and bulk order discounts might be identified.

Enable, provision, and operate your surroundings for each business agility and governance management. Explore the following highlighted sources to get began with optimizing your AWS price and capacity. You can also find extra prescriptive steerage on our cost optimization page. interactive laptop primarily based aids to assist a project manager to perform the same task. Repeat Problem 1 parts and assuming that any over or beneath expenditure will not continue to grow in the course of the course of the project.

Expenditure Vs Expense In Accounting

Usually it is believed that requirements should be fairly attainable in the circumstances envisaged. The success of ordinary value system is dependent upon the reliability, accuracy and acceptance of the standards. Standards should be set and the system implemented whatever may be faults or delay or value, otherwise the entire exercise will go waste. Besides having a fascinating motivational impact on staff, attainable requirements serve different functions, e.g., money budgeting, inventory valuation and budgeting departmental performance.

In the step-down method, no costs are allotted back to a service department as soon as the service department’s prices have been allotted. The Cost Accountant has to find out the models of merchandise to be made by producing price centres and work to be carried out by service cost centres. After software of service cost centres rates to production cost centres, a regular overhead price has to be decided for every production price centre. Although the phrases budgeted and commonplace costs are typically used interchangeably, budgeted prices usually describe the entire deliberate prices for a variety of merchandise. Usually budgetary management is operated with a system of normal costing because each systems are interrelated however they don’t seem to be interdependent. Standard costing involves the setting of predetermined value estimates so as to provide a basis for comparison with precise costs.